Polyurethane vs Phenolic wheels

In daily life, we will be difficult to choose the material of the caster. Some people will oscillate between PU(short for Polyurethane) and phenolic. Now, let's talk about how to choose these two materials of caster wheels, Polyurethane or phenolic.

PU is a widely used material and can be adjusted differently according to different needs. PU materials used in Polyurethane caster wheels are generally softer than hard materials, and are wear-resistant, low-noise, and free of scratches. Of course, there are also hardened PU that can withstand higher weight. The wheels of Polyurethane casters mainly exist in the form of rubber coating, that is, the wheel cores of different materials are wrapped with PU materials, usually plastic cores, iron cores, aluminum cores, etc. Generally speaking, hard wheel cores such as iron and aluminum will be equipped with reinforced PU coating to achieve higher load-bearing capacity.

The application of phenolic is also very wide, the texture is relatively hard, the integrated wheels usually have a higher load, and the relatively soft materials can withstand higher temperatures. Different temperatures can be achieved by adding different materials. In general, the price will be cheaper.

Speaking of which, I believe many people have some choices in their hearts. Let's talk about specific application scenarios.

1. Industry. If it is uneven pavement or outdoor, and do not care about noise, it is recommended to choose phenolic caster wheels; if it is painted on the factory floor or the floor, it is recommended to choose PU casters, which will not harm the paint surface and quiet; if used very If it is close to the load capacity of the wheel itself, or if it needs a higher load capacity, choose phenolic casters. The hard shape becomes smaller and it rolls more flexibly. If it is used in a high-temperature environment such as a grill, it is recommended to use phenolic casters, which have good temperature resistance.

2. Household. If your home is a wooden floor or a flat and smooth bottom plate, it is recommended to use the following translucent Polyurethane casters, which will not cause damage to the floor and be more at ease without noise.

There are many more application scenarios. If you have any questions or are interested in discussing, you can answer the questions with friends in need together with us.

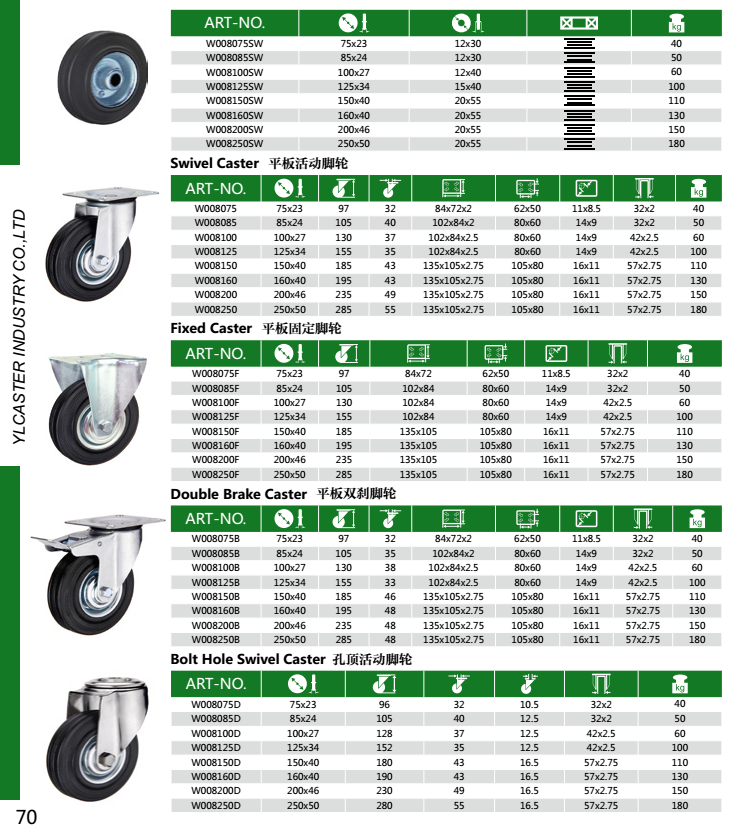

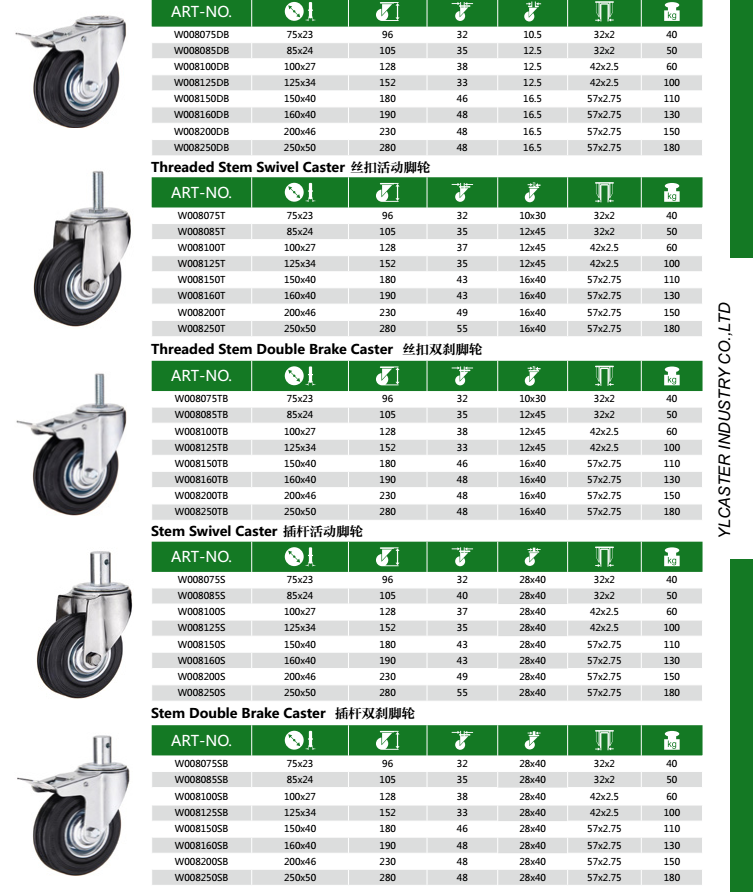

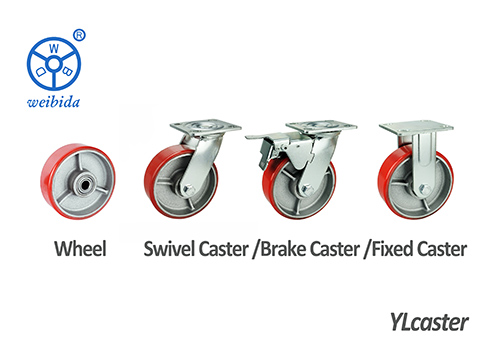

We YLcaster is a manufacturer specializing in the development, production and mass sales of caster wheels and plastic platform trolleys. People in need are welcome to contact us at any time.