Oceanwell Light Luxury Wall-Hung Intelligent Toilet Experience Professional-Grade Smart Bathroom Comfort

The bathroom is the most intimate space in daily life, and a high-quality smart toilet can elevate its functionality and comfort to a new level. Oceanwell's OCWE993 Wall-Hung Intelligent Toilet, designed with rigorous technical standards and user-centric details, perfectly aligns with the core criteria of premium smart toilets. This blog will take you deep into the OCWE993's standout features—from design and hygiene to convenience and operability—showcasing how it integrates professional technology into every daily use scenario. Whether for home renovation or commercial space outfitting, the OCWE993 is a reliable choice that balances performance and practicality.

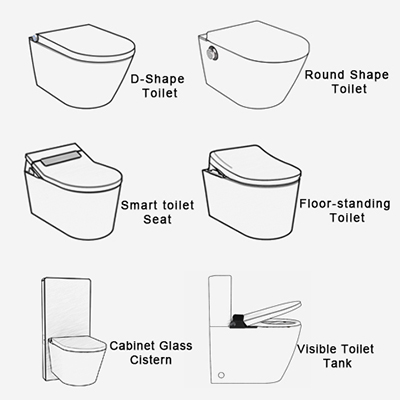

1. Design: Wall-Hung, Rimless & Space-Efficient

The OCWE993's design fully embodies the balance of aesthetics and functionality, tailored to modern bathroom needs.

•Wall-Hung Space-Saving Structure: Mounted directly on the wall, it frees up floor space for easy cleaning (no hard-to-reach gaps) and creates a minimalist, airy atmosphere. Its compact dimensions (575×370×338mm) and 32Kg net weight make installation flexible, suitable for both small bathrooms and large luxury spaces.

•Rimless Innovation: The rimless toilet design eliminates traditional rim gaps, preventing dirt accumulation and simplifying cleaning.

•Durable & Seamless Construction: The streamlined one-piece design integrates all functions without awkward joints, complemented by a quick-release seat and cover for hassle-free maintenance.

2. Hygiene: Multi-Layered Protection for a Clean Experience

Hygiene is at the core of the OCWE993's design, with multiple professional features to ensure cleanliness.

•Dual Self-Cleaning Nozzle: The nozzle automatically cleans before and after each use. For models equipped with the optional UV sterilization function, it initiates 30 seconds of UV disinfection after 30 seconds of idleness (or 12 hours of prolonged idleness), eliminating bacteria effectively.

•Bacteria-Resistant Materials & Structures: The non-porous nozzle surface and rimless design prevent dirt and bacteria buildup. Manual nozzle cleaning is also supported—simply press and hold the rear wash button to extend the nozzle for thorough cleaning.

•Warm-Air Drying System: Replaces traditional toilet paper with adjustable temperature settings, reducing irritation and waste while enhancing comfort.

3. Convenience: Customizable Comfort for Every User

The OCWE993 prioritizes user comfort with thoughtful, adjustable features for all scenarios.

•Heated Seat (Optional): Offers 5 temperature levels (29~37℃, plus OFF mode) to avoid cold discomfort, especially in colder months. The soft-closing seat and cover close silently, preventing noise disruptions.

•Smart Night Light: Defaults to always-on mode, with adjustable settings (ON/OFF) via the remote or bidet button. It provides gentle illumination for nighttime use without dazzling.

•Low-Maintenance Design: The quick-release seat and cover allow easy removal for cleaning. The filter (with a 6-month service life) ensures water quality, and replacement is straightforward when water flow decreases.

4. Accessibility: Intuitive Control for Effortless Operation

The OCWE993 features user-friendly controls and reliable safety mechanisms, ensuring accessibility for all.

•Remote Control: Powered by two 3V batteries, it supports one-on-one pairing (32 optional ID codes) to avoid interference in multi-toilet spaces. The intuitive buttons allow adjustment of all functions, from wash modes to temperature.

•Dual Operation Modes: Functions can be controlled via both the remote and the bidet's side buttons, catering to different user habits. For example, water flow, position, and temperature can be adjusted directly on the bidet for quick tweaks.

•Comprehensive Safety Protections: Equipped with thermal cutoff fuses, liquid level switches, thermostats, and an air gap for backflow prevention. The IPX4 protection rating ensures safe use in humid bathroom environments.

5. Bidet Features: Personalized Cleansing with Professional Modes

The integrated bidet system offers versatile, tailored cleansing experiences for every user.

•Multiple Wash Modes: Includes rear wash, female wash, oscillating spray, pulsating spray, and combined oscillating+pulsating spray. Each mode operates in a fixed position for 10 seconds, followed by 18 seconds of movable spray for thorough cleaning.

•Customizable Parameters: 5 levels of adjustment for water temperature (OFF + 4 heating grades), flow rate (350~650mL/min), and nozzle position, meeting the needs of different ages and body types.

•Massage Function: Switch between normal, oscillating, pulsating, and combined modes via the remote or bidet button, with indicator lights showing the current mode for clarity.

Why the Oceanwell OCWE993 Stands Out?

The OCWE993 isn't just a smart toilet—it's a professional-grade bathroom solution backed by rigorous technical specifications and user-centric design. Based on its official manual, it delivers on every promise: space-saving wall-hung design for practicality and aesthetics, multi-layered hygiene protections for peace of mind, customizable comfort features for all users, intuitive controls for effortless operation, and versatile bidet functions for personalized cleansing.

Whether you're upgrading your home bathroom or equipping a hotel, office, or healthcare facility, the Oceanwell OCWE993 Wall-Hung Intelligent Toilet combines reliability, comfort, and professionalism to transform daily routines into a premium experience. Choose the OCWE993 for a smarter, cleaner, and more comfortable bathroom life.